Starting a print only to hear popping sounds or see messy “stringing” is a clear sign of a common enemy: moisture. This condition, often identified by wet filament symptoms, happens because 3D printing materials are hygroscopic—they literally suck water out of the air. If you don’t have a professional drying machine, don’t panic. (how to dry PLA filament without a dehydrator)

In this guide, we will explore 3D printer filament storage ideas and three safe ways to dry your plastic using everyday household items.

1. The Heated Bed Method (The Safest DIY Hack)

If you own a 3D printer, you already own a filament dryer. Your printer’s heated bed provides a consistent, low-heat surface that is perfect for removing moisture.

- How to do it: Place your filament spool flat on the heated bed. Set the bed temperature to 45-50°C (for PLA). Cover the spool with a cardboard box that has a few small holes poked in the top to let moisture escape.

- Duration: Let it sit for 4–6 hours. This is the most controlled way to fix brittle PLA filament without damaging the spool.

2. Using Your Kitchen Oven (Handle with Care)

A kitchen oven is the fastest method, but it is also the riskiest. Most home ovens have temperature fluctuations that can accidentally melt your entire spool into a plastic puck.

- Pro Tip: Always preheat the oven first and use an external thermometer to verify the temperature stays below 50°C. If your oven cannot maintain a stable low temperature, skip this method to avoid ruining your filament.

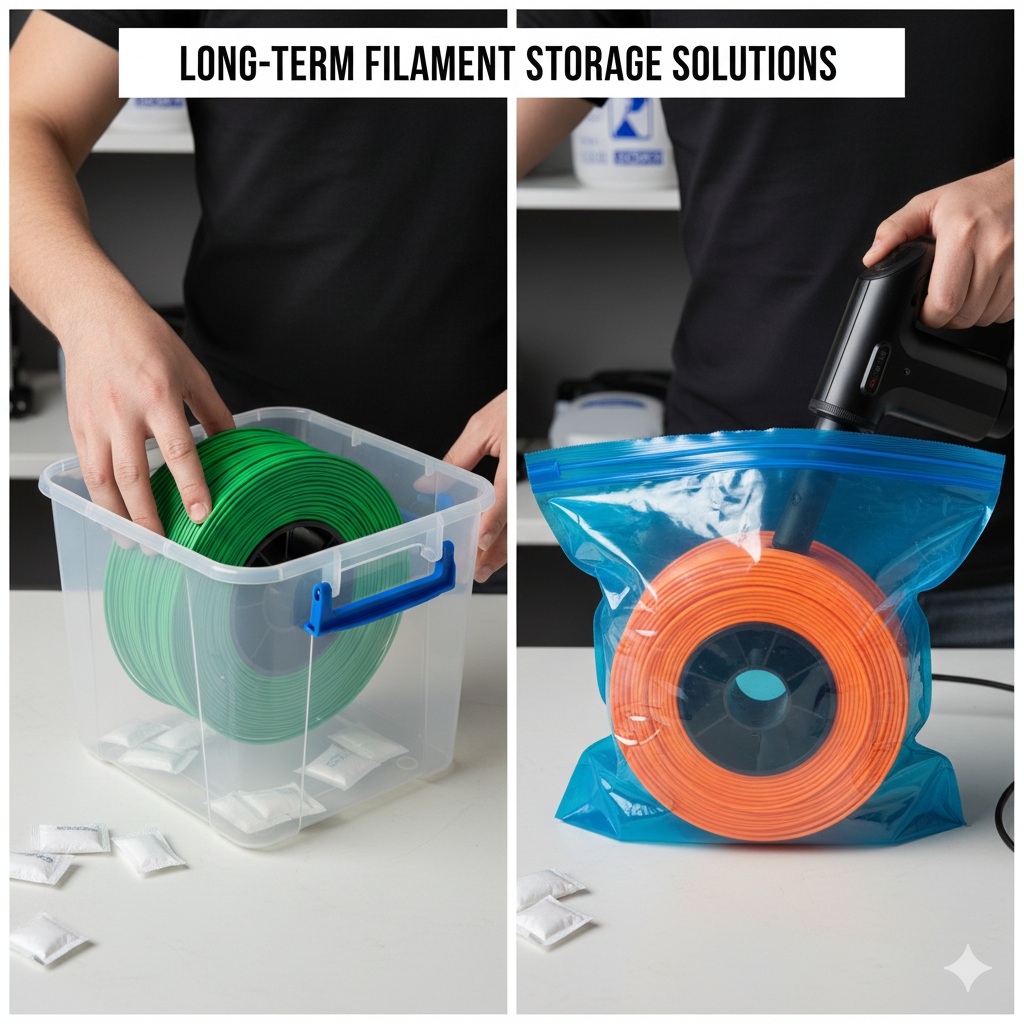

3. Silica Gel and Vacuum Bags

While this is better for prevention, it can slowly pull moisture out of slightly damp rolls.

- The Process: Place your spool in a vacuum-sealed bag or an airtight container with several large desiccant (silica gel) packets. This is a crucial part of long-term storage to ensure your filament stays “crisp” for future projects.

Summary

Printing with wet filament leads to nozzle clogs and failed projects. If a dedicated dryer isn’t in your budget yet, the heated bed method is your best friend. Proper drying combined with a well-calibrated machine will significantly improve your success rate.

Pro Tip: While having dry filament is crucial, using the right software settings is what truly brings out the best in your machine. If you are a Bambu Lab user, make sure to check out our Best Slicers and Software for Bambu Lab 3D Printers (Complete Guide) to ensure your slicer profile is perfectly optimized for these high-speed prints.